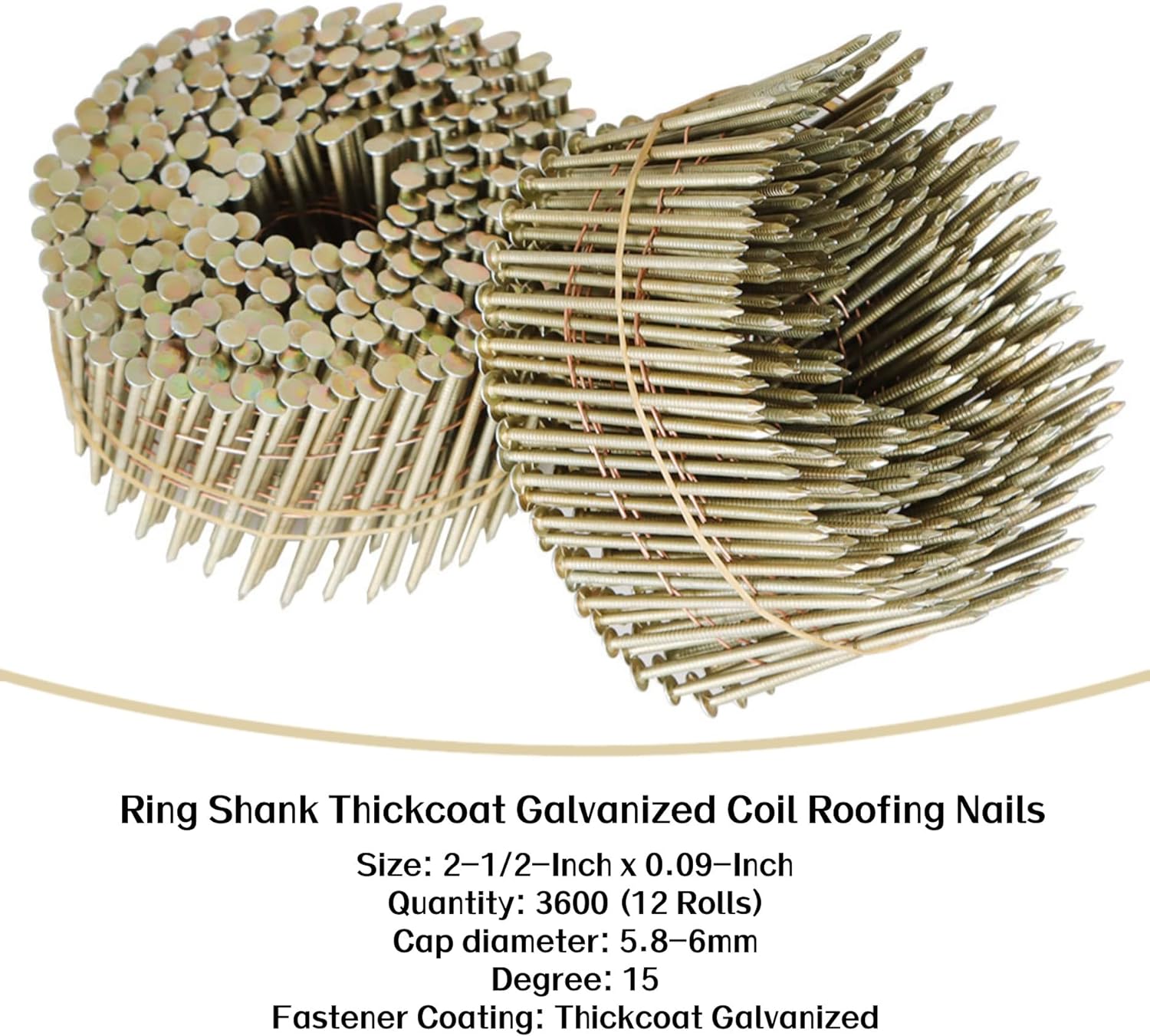

15 Degree Ring Shank Pallet Coil Nails

Product Details of 15 Degree Ring Shank Pallet Coil Nails

15 degree ring shank pallet coil nails are specifically designed for use in pallet construction and other heavy-duty applications. The 15-degree angle of the nails allows for efficient and precise placement, while the ring shank provides superior holding power, making them ideal for securing heavy loads. The coil format allows for quick and continuous nail feeding, reducing downtime and increasing productivity. These nails are commonly used with pneumatic nail guns for fast and efficient installation. Overall, 15 degree ring shank pallet coil nails are a reliable and durable option for demanding construction projects.

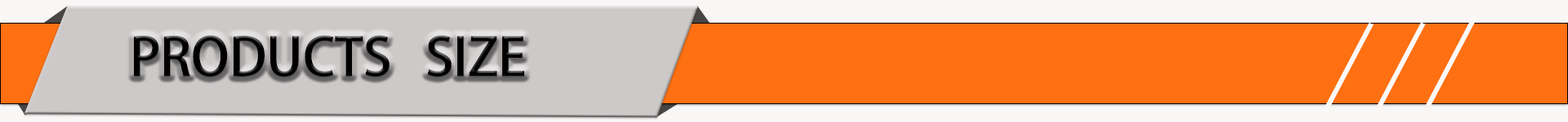

Size of Ring Shank Wire Roofing Coil Nails

| Coiled Nails - Ring Shank | |||

| Length | Diameter | Collation Angle (° ) | Finish |

| (inch) | (inch) | Angle (° ) | |

| 2-1/4 | 0.099 | 15 | Galvanized |

| 2 | 0.099 | 15 | bright |

| 2-1/4 | 0.099 | 15 | bright |

| 2 | 0.099 | 15 | bright |

| 1-1/4 | 0.090 | 15 | 304 stainless steel |

| 1-1/2 | 0.092 | 15 | galvanized |

| 1-1/2 | 0.090 | 15 | 304 stainless steel |

| 1-3/4 | 0.092 | 15 | 304 stainless steel |

| 1-3/4 | 0.092 | 15 | hot dipped galvanized |

| 1-3/4 | 0.092 | 15 | hot dipped galvanized |

| 1-7/8 | 0.092 | 15 | galvanized |

| 1-7/8 | 0.092 | 15 | 304 stainless steel |

| 1-7/8 | 0.092 | 15 | hot dipped galvanized |

| 2 | 0.092 | 15 | galvanized |

| 2 | 0.092 | 15 | 304 stainless steel |

| 2 | 0.092 | 15 | hot dipped galvanized |

| 2-1/4 | 0.092 | 15 | galvanized |

| 2-1/4 | 0.092 | 15 | 304 stainless steel |

| 2-1/4 | 0.090 | 15 | 304 stainless steel |

| 2-1/4 | 0.092 | 15 | hot dipped galvanized |

| 2-1/4 | 0.092 | 15 | hot dipped galvanized |

| 2-1/2 | 0.090 | 15 | 304 stainless steel |

| 2-1/2 | 0.092 | 15 | hot dipped galvanized |

| 2-1/2 | 0.092 | 15 | 316 stainless steel |

| 1-7/8 | 0.099 | 15 | aluminum |

| 2 | 0.113 | 15 | bright |

| 2-3/8 | 0.113 | 15 | galvanized |

| 2-3/8 | 0.113 | 15 | 304 stainless steel |

| 2-3/8 | 0.113 | 15 | bright |

| 2-3/8 | 0.113 | 15 | hot dipped galvanized |

| 2-3/8 | 0.113 | 15 | bright |

| 1-3/4 | 0.120 | 15 | 304 stainless steel |

| 3 | 0.120 | 15 | galvanized |

| 3 | 0.120 | 15 | 304 stainless steel |

| 3 | 0.120 | 15 | hot dipped galvanized |

| 2-1/2 | 0.131 | 15 | bright |

| 1-1/4 | 0.082 | 15 | bright |

| 1-1/2 | 0.082 | 15 | bright |

| 1-3/4 | 0.082 | 15 | bright |

Product show of Ring Shank Wire Roofing Coil Nails

Product Video of 15degree Wire Pallet Coil Nails

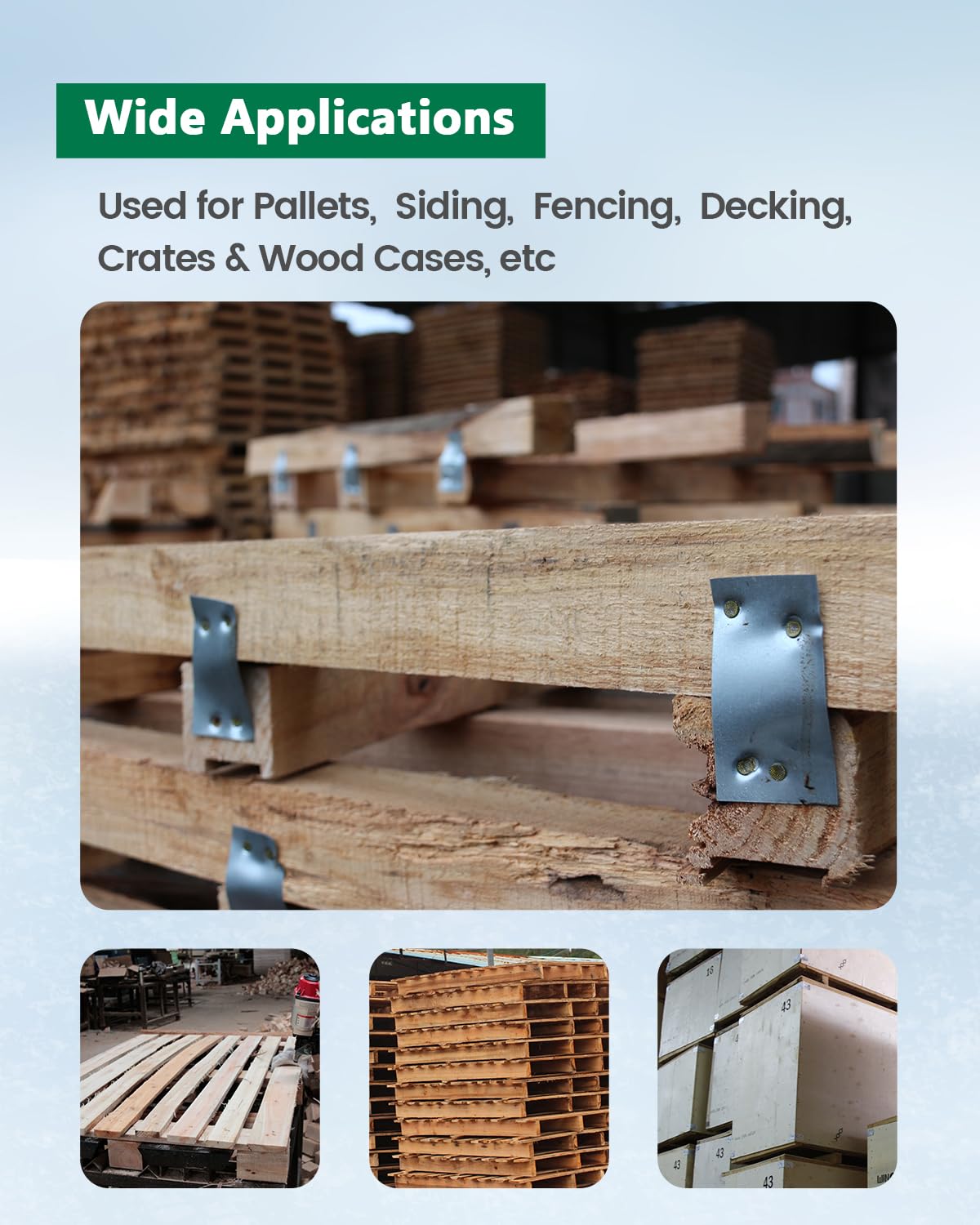

Application of Bright Ring Shank Coil Nails

Bright ring shank coil nails are similar to the 15-degree ring shank pallet coil nails in that they are designed for heavy-duty applications. The "bright" designation typically refers to the finish of the nails, indicating that they have a plain, uncoated surface. This type of finish is often preferred for indoor applications where corrosion resistance is not a primary concern.

The ring shank design provides enhanced holding power, making these nails suitable for use in demanding construction projects where strong and secure fastening is essential. The coil format allows for efficient and continuous nail feeding, reducing the need for frequent reloading and increasing productivity.

Bright ring shank coil nails are commonly used in applications such as framing, sheathing, decking, and other general construction tasks. They are compatible with pneumatic nail guns, making them a convenient and efficient option for fastening a variety of materials.

Overall, bright ring shank coil nails are a reliable choice for heavy-duty construction and carpentry projects where a strong, uncoated nail is required.

Roofing Ring Shank Siding Nails

The packaging for Roofing Ring Shank Siding Nails can vary depending on the manufacturer and distributor. However, these nails are typically packaged in sturdy, weather-resistant containers to protect them from moisture and damage during storage and transportation. Common packaging options for Roofing Ring Shank Siding Nails may include:

1. Plastic or cardboard boxes: Nails are often packaged in durable plastic or cardboard boxes with secure closures to prevent spillage and keep the nails organized.

2. Plastic or paper-wrapped coils: Some Roofing Ring Shank Siding Nails may be packaged in coils wrapped in plastic or paper, allowing for easy dispensing and protection against tangling.

3. Bulk packaging: For larger quantities, Roofing Ring Shank Siding Nails may be packaged in bulk, such as in sturdy plastic or wooden crates, to facilitate handling and storage on construction sites.

It's important to note that the packaging may also include important information such as nail size, quantity, material specifications, and usage instructions. Always refer to the manufacturer's guidelines for proper handling and storage of Roofing Ring Shank Siding Nails.

Bright Finish

Bright fasteners have no coating to protect the steel and are susceptible to corrosion if exposed to high humidity or water. They are not recommended for exterior use or in treated lumber, and only for interior applications where no corrosion protection is needed. Bright fasteners are often used for interior framing, trim and finish applications.

Hot Dip Galvanized (HDG)

Hot dip galvanized fasteners are coated with a layer of Zinc to help protect the steel from corroding. Although hot dip galvanized fasteners will corrode over time as the coating wears, they are generally good for the lifetime of the application. Hot dip galvanized fasteners are generally used for outdoor applications where the fastener is exposed to daily weather conditions such as rain and snow. Areas near the coasts where the salt content in rain water is much higher, should consider Stainless Steel fasteners as salt accelerates the deterioration of the galvanization and will accelerate corrosion.

Electro Galvanized (EG)

Electro Galvanized fasteners have a very thin layer of Zinc that offers some corrosion protection. They are generally used in areas where minimal corrosion protection is needed such as bathrooms, kitchens and other areas that are susceptible to some water or humidity. Roofing nails are electro galvanized because they are generally replaced before the fastener begins to wear and are not exposed to harsh weather conditions if installed properly. Areas near the coasts where salt content in rain water is higher should consider a Hot Dip Galvanized or Stainless Steel fastener.

Stainless Steel (SS)

Stainless steel fasteners offer the best corrosion protection available. The steel may oxidize or rust over time but it will never lose its strength from corrosion. Stainless Steel fasteners can be used for exterior or interior applications and generally come in 304 or 316 stainless steel.