3 inch concrete nail

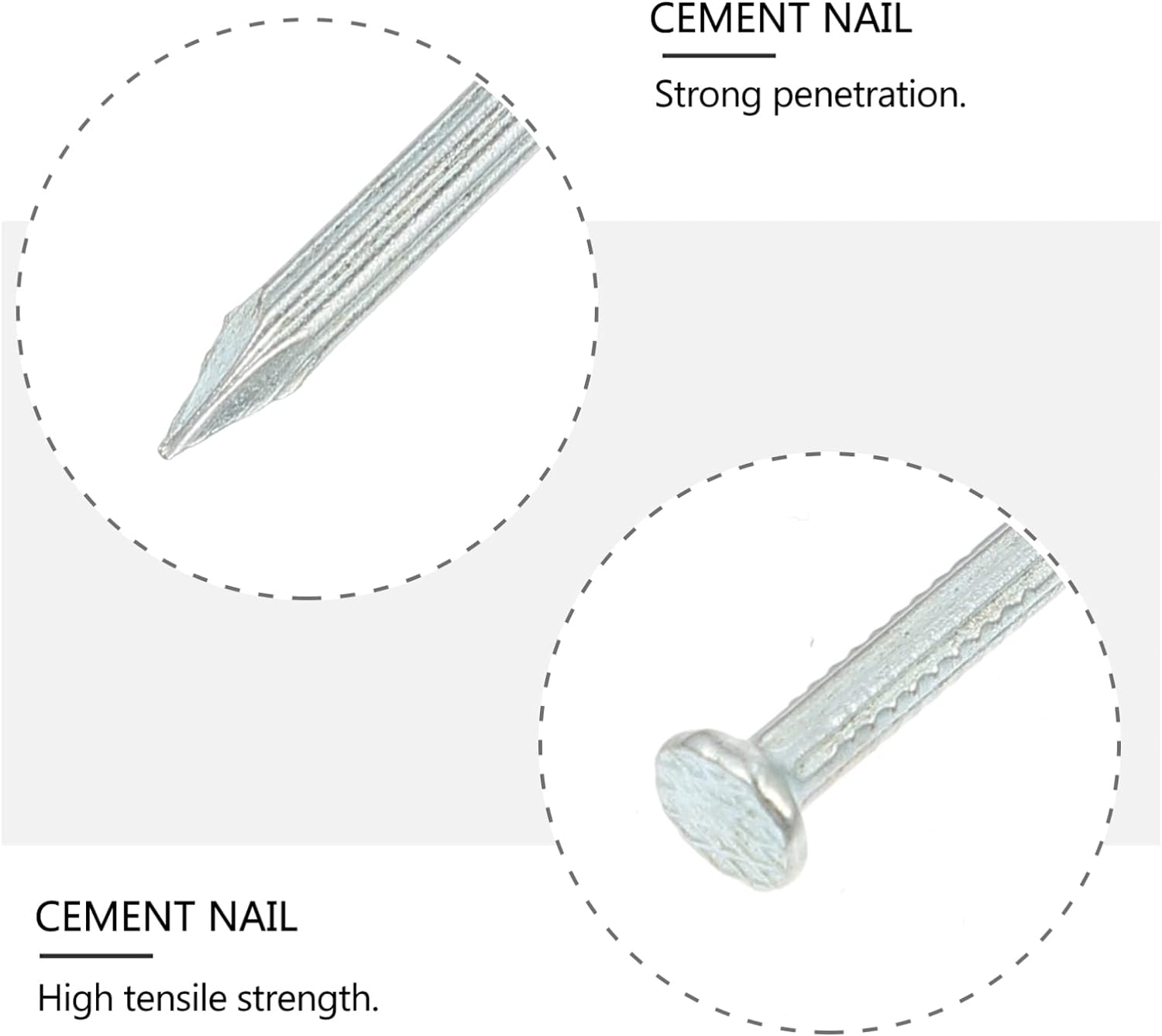

Product Description of concrete wire nails

Concrete wire nails, also known as cement nails, are nails specifically designed to fasten materials to concrete, brick, or masonry surfaces. These nails are usually made of hardened steel wire and have sharp tips that more easily penetrate hard materials. Concrete wire nails are commonly used in a variety of construction and carpentry applications, including:

1. Attach a wooden or metal frame to a concrete or masonry surface.

2. Secure electrical boxes, conduit tape, and plumbing fixtures to concrete walls or floors.

3. Install backing strips to secure finishes such as drywall or paneling to concrete or masonry.

4. Temporary fastening during concrete pouring formwork construction.

When using concrete wire nails, it is important to pre-drill pilot holes in the concrete or masonry to prevent the wire nails from bending or breaking during installation. Additionally, selecting the appropriate nail size and type for a specific application is critical to ensuring a safe and secure attachment.

Concrete Nails Shank Type

There are complete types of steel nails for concrete, including galvanized concrete nails, color concrete nails, black concrete nails, bluish concrete nails with various special nail heads and shank types. Shank types include smooth shank, twilled shank for different substrate hardness. With above features, concrete nails offer excellent piecing and fixing strength for firm and strong sites.

Size For nails for ms concrete nails

Product Video of 4 inch concrete nails

4 inch concrete nails Application

Steel concrete nails are commonly used in various applications in construction and carpentry. Some typical uses for steel concrete nails include:

1. Framing: Steel concrete nails are used to fasten wood framing members to concrete or masonry surfaces, such as attaching baseboards to concrete floors or wall studs to masonry walls.

2. Formwork: In concrete formwork construction, steel concrete nails are used to fix the formwork and panels to the concrete frame, providing temporary support during the concrete pouring and solidification process.

3. Backing strips: Steel concrete nails are used to secure backing strips to concrete or masonry walls, providing a framework for attaching finishes such as drywall or paneling.

4. Electrical and Plumbing: Steel concrete nails can be used to secure electrical boxes, conduit tape, and plumbing fixtures to concrete or masonry surfaces.

5. General Repairs: Steel concrete nails are also used for general repair and maintenance tasks, such as fastening metal brackets, hangers, or other hardware to concrete or masonry.

When using steel nails for concrete, it is important to select the appropriate nail size and type for the specific application and to follow proper installation techniques to ensure safe and secure fixation to the concrete or masonry surface.

3 Inch Steel Concrete Nails Surface Treatment

Bright Finish

Bright fasteners have no coating to protect the steel and are susceptible to corrosion if exposed to high humidity or water. They are not recommended for exterior use or in treated lumber, and only for interior applications where no corrosion protection is needed. Bright fasteners are often used for interior framing, trim and finish applications.

Hot Dip Galvanized (HDG)

Hot dip galvanized fasteners are coated with a layer of Zinc to help protect the steel from corroding. Although hot dip galvanized fasteners will corrode over time as the coating wears, they are generally good for the lifetime of the application. Hot dip galvanized fasteners are generally used for outdoor applications where the fastener is exposed to daily weather conditions such as rain and snow. Areas near the coasts where the salt content in rain water is much higher, should consider Stainless Steel fasteners as salt accelerates the deterioration of the galvanization and will accelerate corrosion.

Electro Galvanized (EG)

Electro Galvanized fasteners have a very thin layer of Zinc that offers some corrosion protection. They are generally used in areas where minimal corrosion protection is needed such as bathrooms, kitchens and other areas that are susceptible to some water or humidity. Roofing nails are electro galvanized because they are generally replaced before the fastener begins to wear and are not exposed to harsh weather conditions if installed properly. Areas near the coasts where salt content in rain water is higher should consider a Hot Dip Galvanized or Stainless Steel fastener.

Stainless Steel (SS)

Stainless steel fasteners offer the best corrosion protection available. The steel may oxidize or rust over time but it will never lose its strength from corrosion. Stainless Steel fasteners can be used for exterior or interior applications and generally come in 304 or 316 stainless steel.