Double-Sided Tooth Anti-Slip Washer

Product Description of Non-Slip Gaskets

Non-slip spacers are spacers specifically designed to prevent sliding or movement between two surfaces. They are typically used in applications that require a secure and stable connection between components. Here are some features and uses of anti-slip spacers: Materials: Non-slip gaskets are typically made from materials with a high coefficient of friction, such as rubber, neoprene, silicone, or cork. These materials provide optimal grip and resistance to sliding or movement. Surface Contour: Non-slip pads often have a patterned or textured surface, which increases their grip and prevents slipping. The contour or design of the surface can vary depending on the specific application or requirements. Impact Resistance: Non-slip pads are designed to withstand impact and pressure. They provide cushioning to help absorb shock or vibration, reducing the risk of damage to connected components. Heat and Chemical Resistance: Non-slip gaskets are typically designed to withstand high temperatures or exposure to chemicals, making them suitable for use in a variety of industrial environments. Customizable: Anti-slip spacers can be customized to meet specific sizes or requirements. They can be manufactured in a variety of shapes and sizes to ensure a precise fit between mating surfaces. Applications: Anti-slip gaskets are commonly used in the automotive, aerospace, machinery, electronics and construction industries. They can be used on different pieces of equipment or structures, including machine enclosures, control panels, electrical cabinets and HVAC systems. The main goal of anti-slip spacers is to provide a safe and stable connection between two surfaces, minimizing the risk of movement or sliding. This can enhance safety, reduce maintenance issues, and improve the overall performance of the equipment or structure.

Product show of Washer Double Sides Toothed

Anti-Loose Embossed washer

Non-Slip Gaskets

Lock Washer with Teeth

Product Video of 65 Mn Anti-Slip Washer

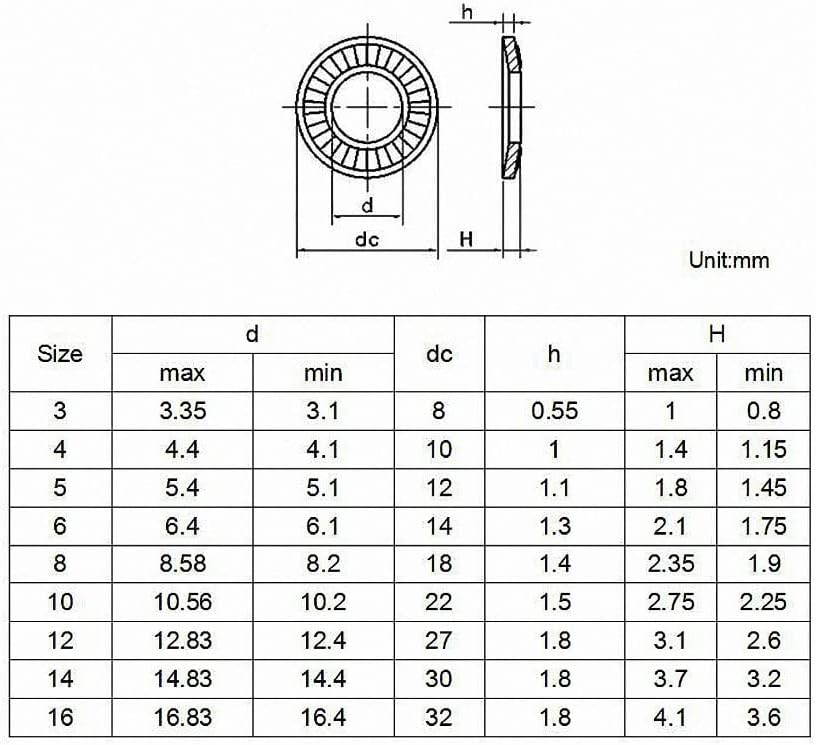

Product size of Double-Sided Tooth Anti-Slip Pad

Application of Spring washers

Anti-slip washers, also known as lock washers, are specifically designed to prevent fasteners from loosening or rotating due to vibration or external force. Here are some common uses for anti-slip washers: Tighten Bolts and Nuts Securely: Non-slip washers are often used in applications where bolts and nuts must be prevented from loosening. These washers provide additional rotational resistance and help keep the fastener in place. Automotive and Transportation Industries: Anti-slip washers are widely used in the automotive and transportation industries where vibration and movement can cause fasteners to loosen over time. They are commonly found in engine components, suspension systems, and other high-vibration areas of the vehicle. Machinery and Equipment Assembly: In industrial machinery and equipment, anti-slip washers are often used to ensure that critical components, such as motor mounts, gearboxes and bearing housings, remain securely tightened even in high-vibration environments. Building and Construction Applications: Anti-slip washers are used in building and construction applications where structural integrity is critical. They help prevent bolts from loosening, ensuring the stability and safety of structures such as bridges, buildings and scaffolding. Electrical and Electronics: Non-slip washers can be used to secure electrical components, such as junction boxes, panels or circuit breakers, to prevent them from loosening due to vibration or other external forces. Pipes and Fittings: In pipe applications, anti-slip washers are used to secure pipe joints and fittings. They provide additional rotational resistance, prevent leaks and maintain the integrity of the duct system. Anti-slip washers are a reliable solution to prevent loosening of fasteners and ensure the stability and safety of various components and structures. Their use is important in any application where vibration, movement, or external forces may cause fasteners to loosen over time.