Headless Steel Nails

Headless Steel Nails

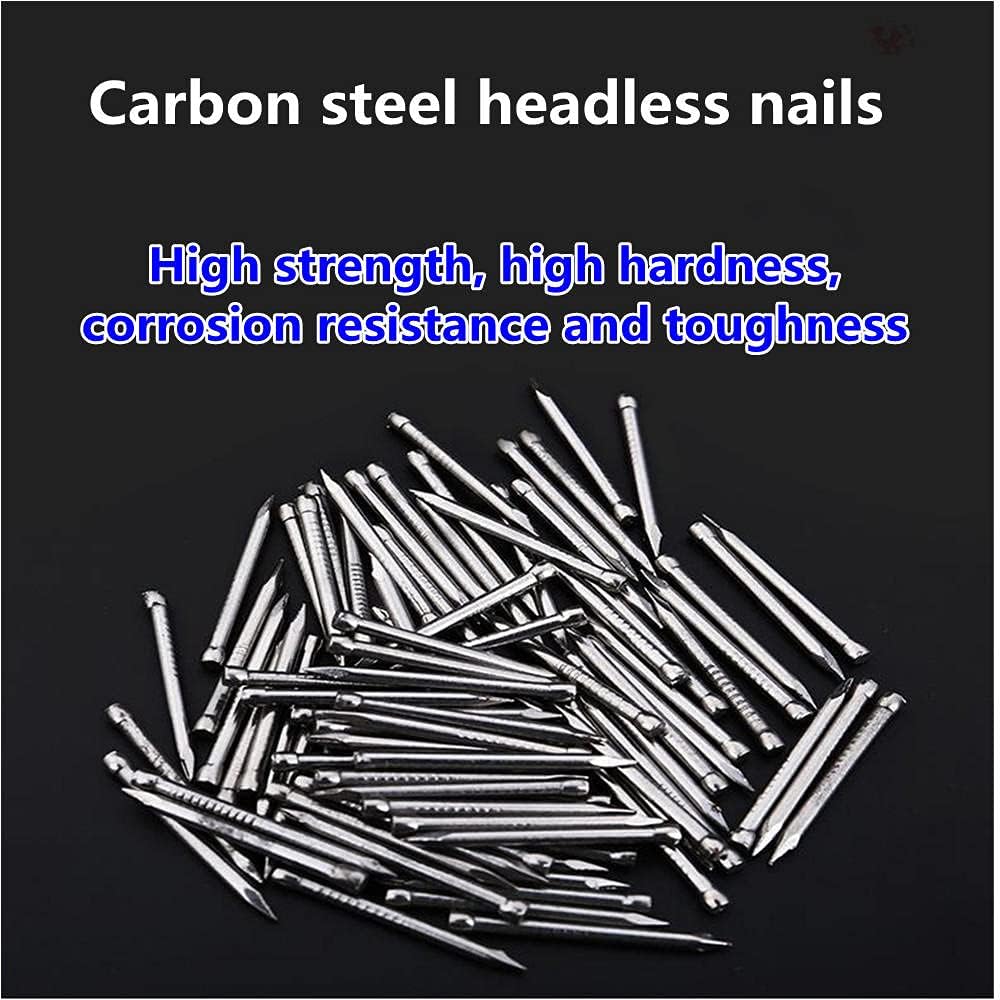

Headless steel nails are nails that do not have a visible head. They are designed to be driven into a surface and then covered over, leaving a smooth finish. These nails are commonly used in applications where a flush or hidden finish is desired, such as in woodworking, trim work, and finishing carpentry. They are available in various lengths and gauges to suit different projects and materials. When using headless steel nails, it's important to use appropriate tools and techniques to ensure they are driven in securely and effectively.

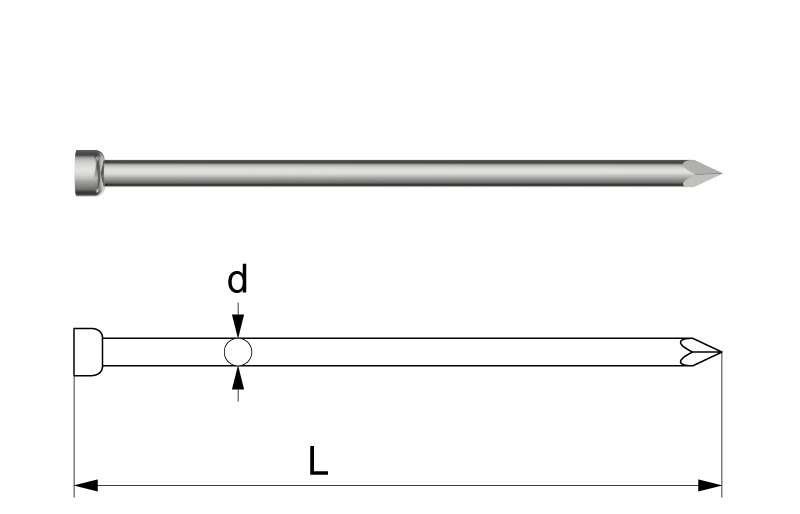

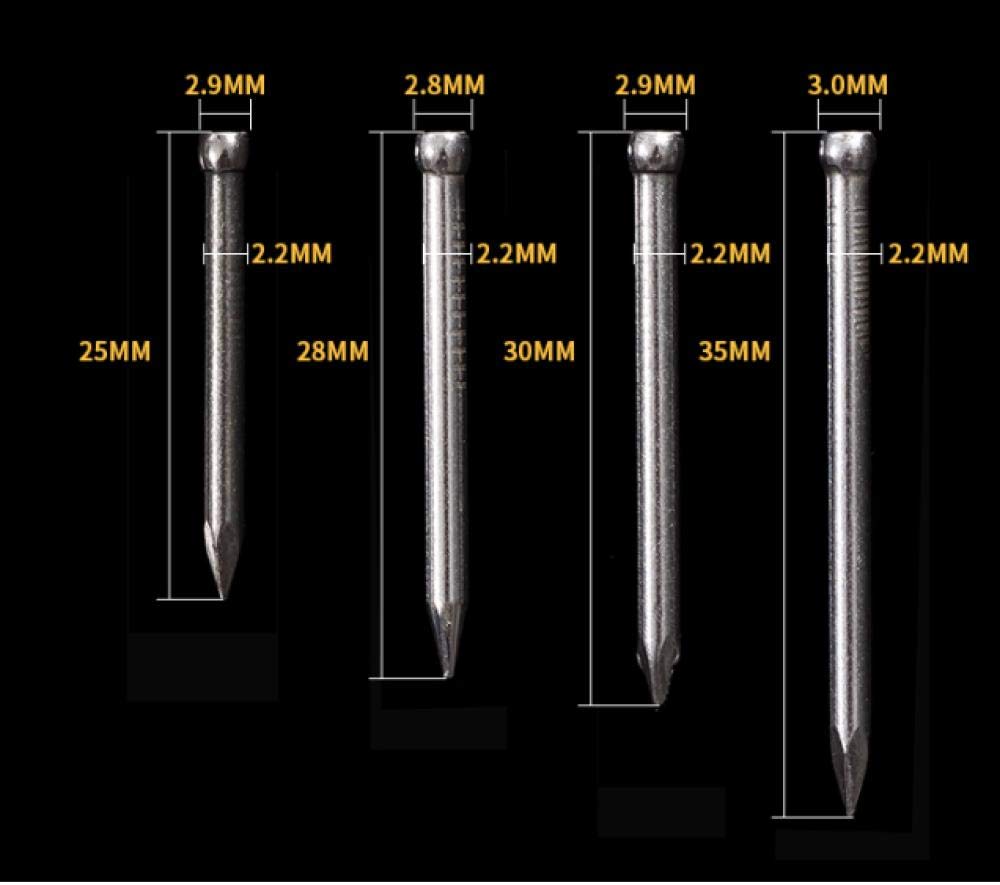

Size For Bright Lost Head Nails

| Length | Gauge | |

| (Inches) | (MM) | (B.W.G) |

| 1/2 | 12.700 | 20/19/18 |

| 5/8 | 15.875 | 19/18/17 |

| 3/4 | 19.050 | 19/18/17 |

| 7/8 | 22.225 | 18/17 |

| 1 | 25.400 | 17/16/15/14 |

| 1-1/4 | 31.749 | 16/15/14 |

| 1-1/2 | 38.099 | 15/14/13 |

| 1-3/4 | 44.440 | 14/13 |

| 2 | 50.800 | 14/13/12/11/10 |

| 2-1/2 | 63.499 | 13/12/11/10 |

| 3 | 76.200 | 12/11/10/9/8 |

| 3-1/2 | 88.900 | 11/10/9/8/7 |

| 4 | 101.600 | 9/8/7/6/5 |

| 4-1/2 | 114.300 | 7/6/5 |

| 5 | 127.000 | 6/5/4 |

| 6 | 152.400 | 6/5/4 |

| 7 | 177.800 | 5/4 |

Products Show of no headl steel nails

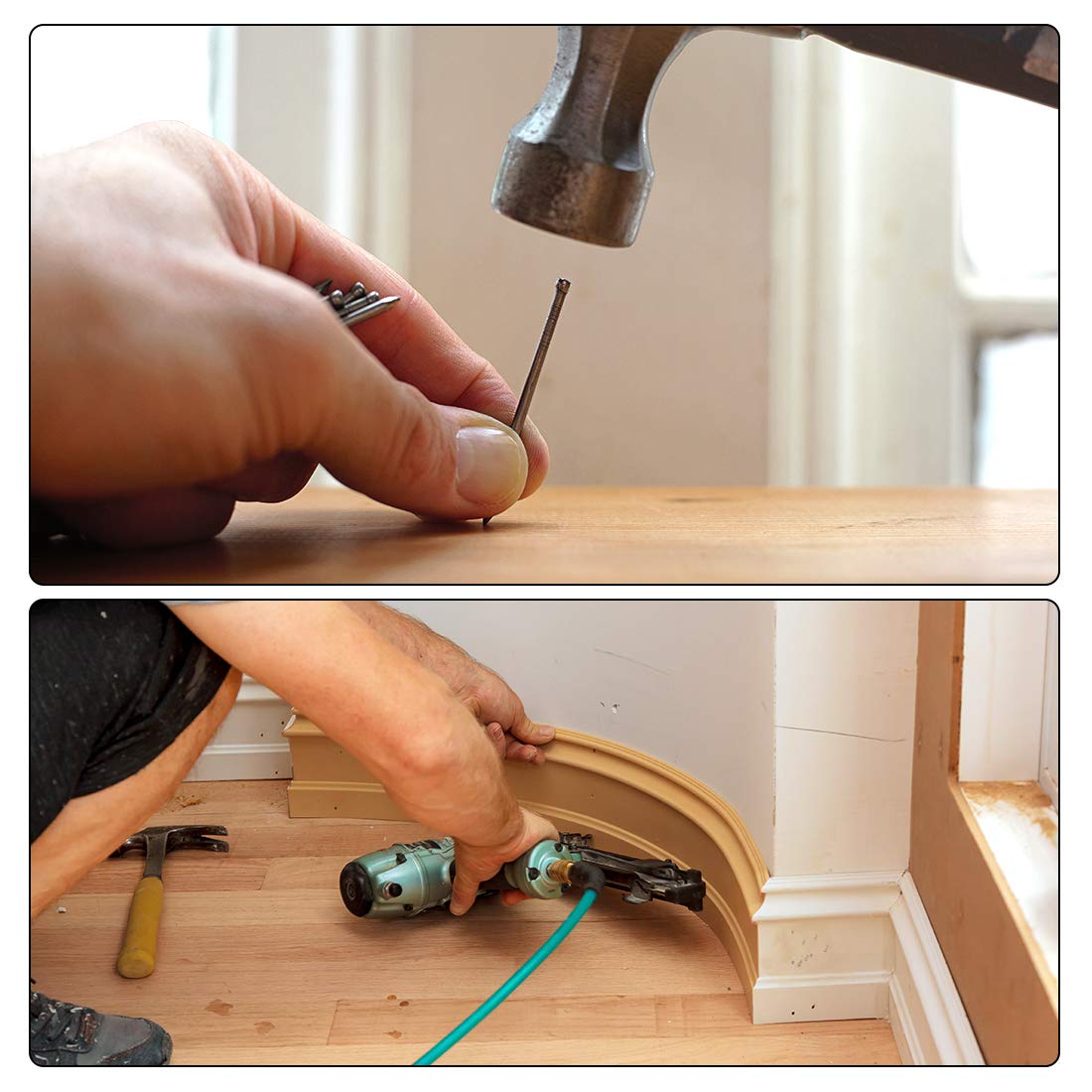

Wood Panel Headless Nails Application

Wood panel headless nails are commonly used in the installation of wood paneling. These nails are designed to be driven into the paneling without leaving a visible head, creating a seamless and smooth finish. They are often used in interior wall paneling, wainscoting, and other decorative wood applications where a clean and polished appearance is desired.

When using wood panel headless nails, it's important to select the appropriate length and gauge to ensure they provide secure fastening without splitting the wood. Additionally, using a nail gun or a hammer and nail set can help to drive the nails flush with the surface, creating a professional and finished look.

It's also important to consider the type of wood being used and the surrounding environment to select the right material and coating for the nails to prevent corrosion and ensure long-lasting performance.

Package of Galvanised Round Wire Nail

1.25kg/strong bag: woven bag or gunny bag

2.25kg/paper carton, 40 cartons/pallet

3.15kg/bucket, 48buckets/pallet

4.5kg/box, 4boxes/ctn, 50 cartons/pallet

5.7lbs/paper box, 8boxes/ctn, 40cartons/pallet

6.3kg/paper box, 8boxes/ctn, 40cartons/pallet

7.1kg/paper box, 25boxes/ctn, 40cartons/pallet

8.500g/paper box, 50boxes/ctn, 40cartons/pallet

9.1kg/bag, 25bags/ctn, 40cartons/pallet

10.500g/bag, 50bags/ctn, 40cartons/pallet

11.100pcs/bag, 25bags/ctn, 48cartons/pallet

12. Other customized