High Performacne Wafer Head Construction Screw

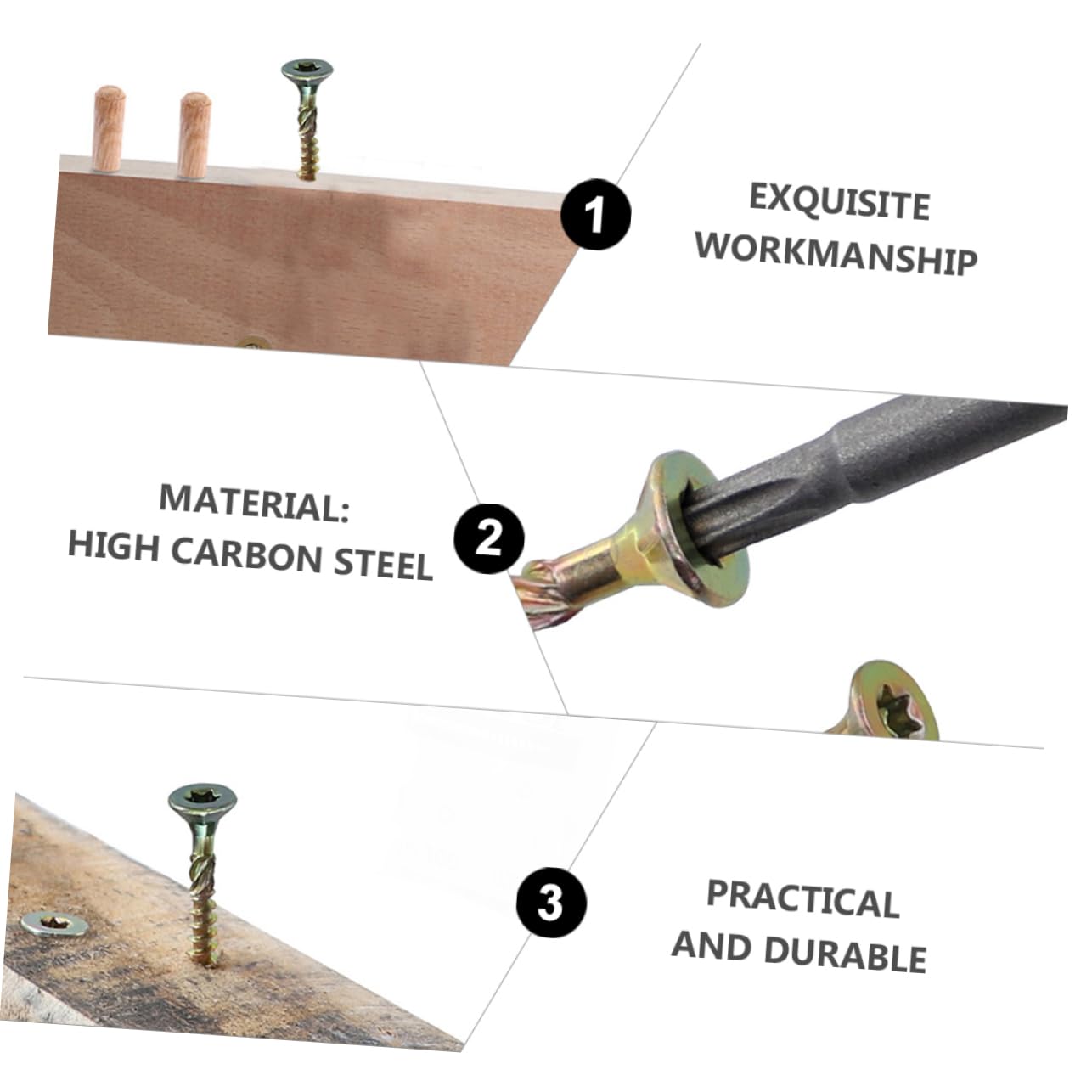

Product Description of High Performance Wood Screw

High performance wood screws are commonly used in a variety of demanding woodworking applications. These screws are designed to provide excellent load-bearing capacity, durability, and resistance to a wide range of environmental conditions. Some common uses for high-performance wood screws include:

1. Outdoor Construction: High-performance wood screws are ideal for outdoor projects such as building decks, fences, gazebos and other outdoor structures. They are designed to withstand the effects of moisture, temperature changes and other outdoor factors.

2. Heavy-Duty Framing: These screws are suitable for heavy-duty framing applications, including building wood frames for buildings, sheds, and other structures that require strong, reliable connections.

3. Structural carpentry: High-performance wood screws are often used in structural carpentry, such as timber structural framing, where these screws need to provide superior strength and stability to the overall structure.

4. Hardwood Applications: They are suitable for hardwoods and denser wood species where standard screws may struggle to provide adequate load-bearing capacity.

Overall, high-performance wood screws are ideal for demanding woodworking projects where superior strength, durability and resistance to environmental factors are required.

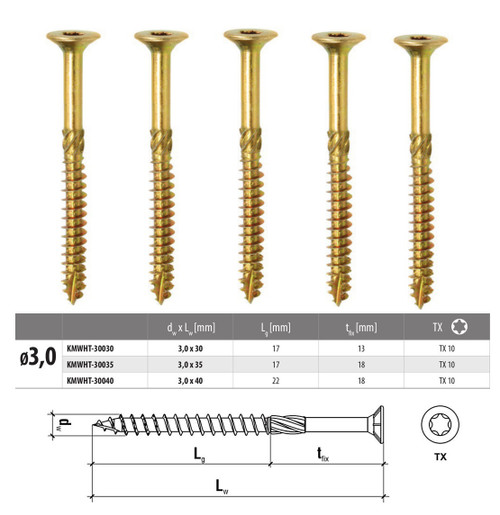

Product Size of High Performacne Carpenter Screws

Product Show of Countersunk Wood Screws

Torx wood timber construction screws are commonly used in a variety of timber construction and woodworking applications. The Torx drive design provides excellent grip and torque transfer, making these screws suitable for heavy-duty and demanding projects. Some common uses for Torx wood timber construction screws include:

1. Timber Framing: These screws are often used in timber framing applications, such as constructing wooden frames for buildings, pergolas, and other timber structures where strong and reliable connections are essential.

2. Decking and Outdoor Structures: Torx wood screws are suitable for building decks, outdoor furniture, and other outdoor timber structures due to their resistance to corrosion and ability to provide secure fastening in outdoor environments.

3. Structural Woodwork: They are used in structural woodwork projects where a high level of strength and stability is required, such as in the construction of wooden beams, trusses, and load-bearing timber elements.

Overall, Torx wood timber construction screws are well-suited for heavy-duty timber construction and woodworking applications, providing reliable and durable fastening in various timber projects.

Package details of Yellow zinc torx drive double countersunk head wood chipboard screw

1. 20/25kg per Bag with customer’s logo or neutral package;

2. 20/25kg per Carton(Brown /White /Color) with customer’s logo ;

3. Normal Packing :1000/500/250/100PCS per Small box with big carton with pallet or without pallet;

4.1000g/900g/500g per Box (Net Weight or gross weight )

5.1000PCS/1KGS per plastic bag with Carton

6.we make all pacakge as customers' request

FAQ

Q: Are you trading company or manufacturer ?