Coil nails are a type of fastener commonly used in construction and carpentry projects. They are designed for use with a coil nail gun, which allows for quick and efficient installation. Coil nails come in various types, each suited for specific applications. Understanding the classification and usage guidance of coil nails is essential for ensuring the success of any project. In this article, we will explore the different types of coil nails, their shank variations, and their respective applications.

Classification of Coil Nails:

Smooth shank coil nails are characterized by their straight and untextured surface. They are commonly used in applications where a strong grip is required, such as in framing, sheathing, and decking. The smooth shank design provides excellent holding power, making it suitable for heavy-duty construction projects. Additionally, smooth shank coil nails are ideal for use in hardwoods and dense materials due to their ability to penetrate and hold securely.

2. Ring Shank Coil Nail:

Ring shank coil nails feature a series of concentric rings along the shank, providing enhanced holding power. The rings create friction when driven into the material, preventing the nail from backing out over time. This type of coil nail is well-suited for applications where high withdrawal resistance is essential, such as in roofing, siding, and fencing. The ring shank design ensures a secure and long-lasting attachment, making it a popular choice for outdoor and structural projects.

3. Screw Shank Coil Nail:

Screw shank coil nails are distinguished by their helical or twisted design, resembling the threads of a screw. This unique configuration offers superior holding strength and resistance to pull-out forces. Screw shank coil nails are commonly used in applications where maximum grip is required, such as in pallet assembly, crate construction, and heavy-duty packaging. The screw-like threads provide exceptional holding power, making them an ideal choice for securing materials that are prone to movement or vibration.

Usage Guidance of Coil Nails:

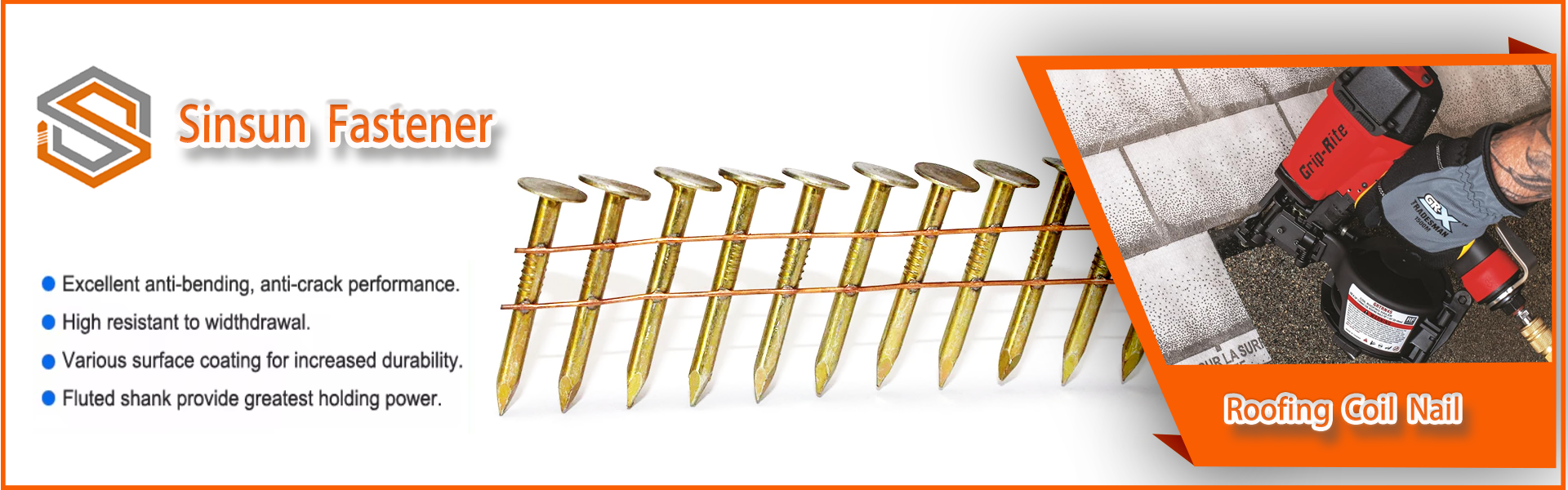

- Roofing Coil Nail:

Roofing coil nails, typically featuring a ring shank design, are specifically designed for securing asphalt and fiberglass shingles, as well as roofing felt. The ring shank provides excellent resistance to wind uplift and ensures a secure attachment of roofing materials. When using roofing coil nails, it is important to drive the nails flush with the surface to prevent water infiltration and maintain the integrity of the roof system.

Siding Coil Nail:

Siding coil nails, available with both smooth and ring shanks, are designed for fastening exterior siding materials, including vinyl, wood, and fiber cement. The choice of shank type depends on the specific siding material and the required holding strength. Smooth shank coil nails are suitable for softer siding materials, while ring shank coil nails are preferred for more rigid and heavy-duty siding applications.

- Pallet Coil Nail:

Pallet coil nails, featuring a screw shank design, are commonly used in the construction and repair of wooden pallets and crates. The screw-like threads of the nails provide exceptional grip and resistance to pull-out forces, ensuring the structural integrity of the pallets. When using pallet coil nails, it is important to drive the nails at an angle to maximize their holding power and prevent wood splitting.

In conclusion, understanding the classification and usage guidance of coil nails is crucial for selecting the appropriate type of nail for a specific application. Whether it is for framing, roofing, siding, or pallet assembly, choosing the right coil nail with the suitable shank type is essential for achieving a secure and long-lasting attachment. By considering the specific requirements of the project and the characteristics of each type of coil nail, professionals and DIY enthusiasts can ensure the success and durability of their construction and carpentry endeavors.

Post time: Jul-11-2024