When it comes to fastening materials together, screws are an essential component. They come in various types and sizes, each designed for specific purposes. Two common types of screws used in woodworking and construction are coach screws and wood screws. While they may appear similar at first glance, there are distinct differences between the two.

Coach screws, also known as lag screws, and wood screws, including the Sinsun fastener, are both used for securing wood, but they serve different functions and have unique characteristics. Understanding the differences between coach screws and wood screws is crucial for selecting the right fastener for a particular application.

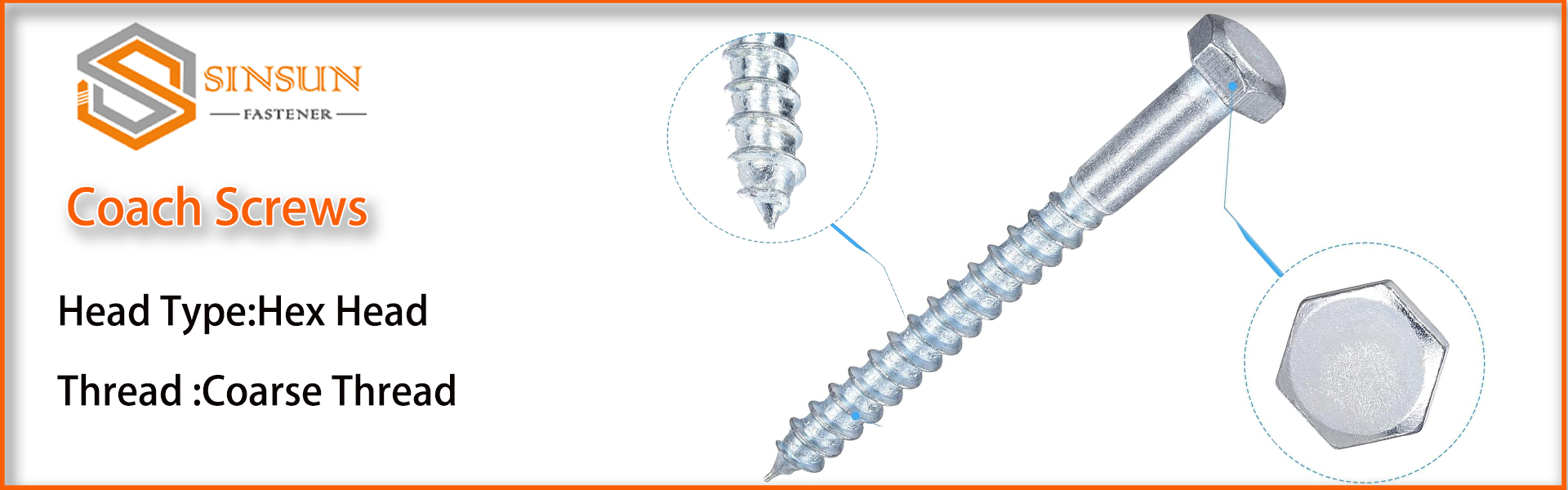

Coach screws are heavy-duty screws with a square or hexagonal head and a coarse thread. They are commonly used for fastening heavy timber, securing metal brackets, and attaching fixtures to wood, such as hinges and gate latches. The coarse thread of coach screws provides a strong grip and makes them suitable for applications where high levels of torque are required. These screws are often used in construction and carpentry projects due to their robust nature and ability to provide a secure hold.

On the other hand, wood screws are designed for general-purpose fastening in wood. They have a sharp point, a tapered shank, and a finer thread compared to coach screws. Wood screws are available in various head types, including flat head, round head, and oval head, making them suitable for different applications. They are commonly used in furniture making, cabinetry, and other woodworking projects where a neat and flush finish is desired.

One of the key differences between coach screws and wood screws lies in their intended applications. Coach screws are primarily used for heavy-duty tasks, such as securing large timber beams or constructing wooden structures, where their strong grip and robust design are essential. In contrast, wood screws are more versatile and can be used for a wide range of woodworking and general construction applications, including joining wood pieces, installing hardware, and assembling furniture.

Another notable distinction is the head design of coach screws and wood screws. Coach screws typically feature a larger, more prominent head, which allows for greater torque to be applied during installation. This makes them suitable for applications where the screw head needs to withstand significant force without stripping or becoming damaged. Wood screws, on the other hand, have a smaller and more discreet head, which is designed to sit flush with the surface of the wood, providing a clean and professional appearance.

In terms of material composition, both coach screws and wood screws are available in various materials, including steel, stainless steel, and brass. The choice of material depends on the specific requirements of the application, such as corrosion resistance or load-bearing capacity. Sinsun fasteners, a renowned manufacturer of screws and fastening solutions, offers a wide range of coach screws and wood screws in different materials to cater to diverse needs.

When selecting between coach screws and wood screws, it is essential to consider the specific requirements of the project. Factors such as the type of wood being used, the load-bearing capacity needed, and the aesthetic considerations will influence the choice of screw. Additionally, the size and length of the screw should be carefully chosen to ensure a secure and reliable fastening.

In conclusion, while coach screws and wood screws are both used for fastening wood, they serve distinct purposes and have unique characteristics. Coach screws are heavy-duty fasteners designed for robust applications, while wood screws are versatile and suitable for general woodworking tasks. Understanding the differences between these two types of screws is essential for selecting the right fastener for any woodworking or construction project. Whether it's a heavy-duty construction job or a delicate woodworking project, choosing the appropriate screw can make a significant difference in the strength, durability, and overall quality of the finished product.

Post time: Jun-19-2024