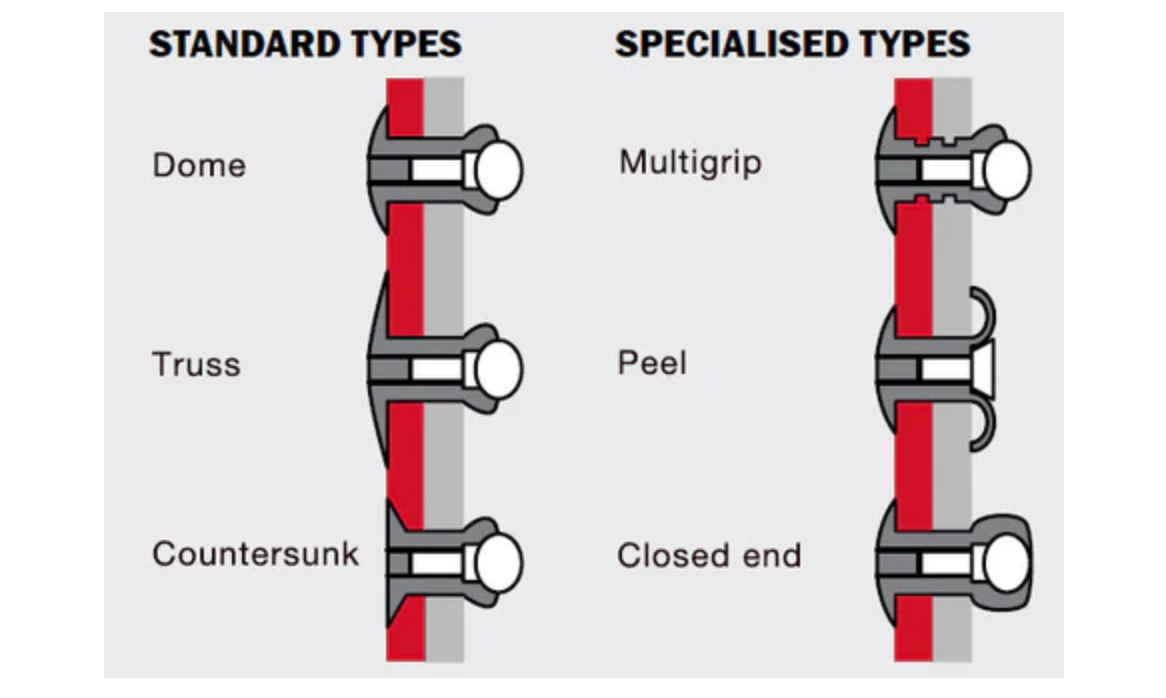

Pop rivets, also known as blind rivets, are a versatile and widely used fastening solution in various industries. They are designed to be inserted from just one side of a joint, making them ideal for fabrication and assembly tasks when access to both sides of the workpiece is restricted. Pop rivets come in a variety of types, each with its own unique features and applications. In this article, we will explore the different types of pop rivets and their specific uses, including the various head styles such as countersunk head blind, standard blind rivets, sealed blind rivets, peeled blind rivets, grooved blind rivets, multi-grip blind rivets, open end blind rivet, and large head blind rivets.

1. Countersunk Head Blind Rivets

Countersunk head blind rivets are a type of fastener used to join two or more materials together. The countersunk head design allows the rivet to sit flush with the surface of the materials being joined, creating a smooth and finished appearance.

These rivets are commonly used in applications where a flush finish is desired, such as in the assembly of furniture, automotive components, and sheet metal fabrication. They are also used in construction, aerospace, and marine industries.

Countersunk head blind rivets are easy to install and do not require access to the back of the materials being joined, making them ideal for applications where one side of the joint is not accessible. They provide a strong and reliable fastening solution for a wide range of materials, including metal, plastic, and composite materials.

Standard blind rivets, also known as pop rivets, are a type of fastener used to join two or more materials together. They consist of a cylindrical body with a mandrel (a shaft) through the center. When the mandrel is pulled, it expands the rivet body, creating a secure joint.

Standard blind rivets are commonly used in a wide range of applications, including automotive assembly, construction, HVAC systems, and general manufacturing. They are particularly useful in situations where access to the back of the materials being joined is limited or impossible.

These rivets are available in various materials, such as aluminum, steel, and stainless steel, making them suitable for use with different types of materials. They are easy to install and provide a strong, vibration-resistant joint. Standard blind rivets are also available in different head styles, such as dome head, large flange head, and countersunk head, to suit various application requirements.

Sealed blind rivets, also known as sealed pop rivets, are a type of fastener designed to provide a watertight or airtight seal when installed. They are commonly used in applications where preventing the ingress of water, dust, or other contaminants is essential.

The sealed blind rivets feature a specially designed mandrel that, when pulled, expands the rivet body and compresses a sealing washer or O-ring against the materials being joined. This creates a tight seal, making them suitable for use in outdoor, marine, or automotive applications where exposure to the elements is a concern.

These rivets are often used in the assembly of outdoor furniture, automotive components, HVAC systems, and other applications where a watertight or airtight seal is required. Sealed blind rivets are available in various materials and head styles to accommodate different material types and aesthetic preferences.

Peeled blind rivets, also known as peel rivets, are a type of fastener that is designed to provide a large blind side bearing area, making them suitable for use with brittle or soft materials. The "peel" in their name refers to the way the rivet body splits into petals or segments when the mandrel is pulled, creating a large flange on the blind side of the joint.

These rivets are commonly used in applications where a strong, vibration-resistant joint is required, such as in the assembly of appliances, electronics, and automotive components. They are particularly useful for joining materials like plastics, composites, and thin sheet metal, where traditional rivets may cause damage or deformation.

Peeled blind rivets are available in various materials and head styles to accommodate different application requirements. Their ability to provide a large bearing area and a secure grip makes them suitable for a wide range of industrial and manufacturing applications.

Grooved blind rivets, also known as ribbed blind rivets, are a type of fastener that features grooves or ribs along the rivet body. These grooves provide enhanced grip and resistance to rotation when installed, making them suitable for applications where a secure and stable joint is required.

These rivets are commonly used in applications where the materials being joined are prone to movement or vibration, such as in the assembly of machinery, appliances, and automotive components. The grooves on the rivet body help to prevent loosening and provide a more reliable and durable connection.

Grooved blind rivets are available in various materials and head styles to accommodate different application requirements. Their ability to resist rotation and provide a secure grip makes them suitable for a wide range of industrial and manufacturing applications where stability and reliability are essential.

Multi-grip blind rivets, also known as grip range blind rivets, are a type of fastener designed to accommodate a range of material thicknesses. They feature a unique design that allows them to securely fasten materials of varying thicknesses, reducing the need for multiple rivet sizes.

These rivets are commonly used in applications where the thickness of the materials being joined may vary, such as in the assembly of sheet metal, plastic components, and other materials with inconsistent thicknesses. The ability to accommodate a range of material thicknesses makes them versatile and cost-effective for a wide range of applications.

Multi-grip blind rivets are available in various materials and head styles to accommodate different application requirements. Their versatility and ability to adapt to varying material thicknesses make them suitable for use in industries such as automotive, construction, and general manufacturing, where flexibility in fastening solutions is essential.

7. Large Head Blind Rivets

Large head blind rivets, as the name suggests, are blind rivets with a larger head size compared to standard blind rivets. The larger head provides a greater load-bearing surface and can distribute the load more effectively, making them suitable for applications where a strong and secure joint is required.

These rivets are commonly used in heavy-duty applications such as construction, structural steelwork, and industrial equipment assembly. The larger head size allows for better clamping force and resistance to pull-through, making them ideal for joining thick or heavy materials.

Large head blind rivets are available in various materials and head styles to accommodate different application requirements. Their ability to provide a strong and secure joint makes them suitable for a wide range of industrial and manufacturing applications where robust fastening solutions are essential.

8.Open end blind rivets

Open end blind rivets, also known as break stem rivets, are a type of fastener commonly used to join materials together. They feature a hollow body and a mandrel that is pulled through the rivet, causing the end of the rivet to expand and form a second head, creating a secure joint.

These rivets are versatile and can be used in a wide range of applications, including automotive assembly, construction, HVAC systems, and general manufacturing. They are particularly useful in situations where access to the back of the materials being joined is limited or impossible.

Open end blind rivets are available in various materials and head styles to accommodate different application requirements. Their ease of installation and ability to provide a strong, vibration-resistant joint make them suitable for a variety of materials and applications.

When selecting the appropriate type of pop rivet for a specific application, it is important to consider factors such as the material thickness, joint configuration, environmental conditions, and desired finished appearance. Additionally, the installation process and equipment required should also be taken into account to ensure a successful and reliable fastening solution.

In conclusion, pop rivets are a versatile and efficient fastening solution for a wide range of applications. With various types of pop rivets available, including countersunk head blind, standard blind rivets, sealed blind rivets, peeled blind rivets, grooved blind rivets, multi-grip blind rivets, open end blind rivet, and large head blind rivets, there is a suitable option for every fastening need. By understanding the specific features and applications of each type of pop rivet, manufacturers and fabricators can make informed decisions to achieve strong, secure, and aesthetically pleasing assemblies.

Post time: Jun-26-2024