Ring Shank Cold-Dipped Galvanized Collated Wire Coil Nails

Product Details of Ring Shank Cold-Dipped Galvanized Collated Wire Coil Nails

Ring shank cold-dipped galvanized collated wire coil nails are commonly used in exterior construction applications where corrosion resistance and strong holding power are essential. The cold-dipped galvanized coating provides excellent protection against rust and corrosion, making these nails suitable for outdoor use, particularly in siding, decking, and roofing projects.

The ring shank design offers enhanced holding power, ensuring a secure attachment to wooden surfaces. The collated wire coil format allows for efficient and continuous nail feeding, reducing the need for frequent reloading and increasing productivity during construction tasks.

These nails are often used with pneumatic nail guns for fast and efficient installation. The combination of cold-dipped galvanized coating, ring shank design, and collated wire coil format makes ring shank cold-dipped galvanized collated wire coil nails a reliable and durable option for a wide range of exterior construction projects.

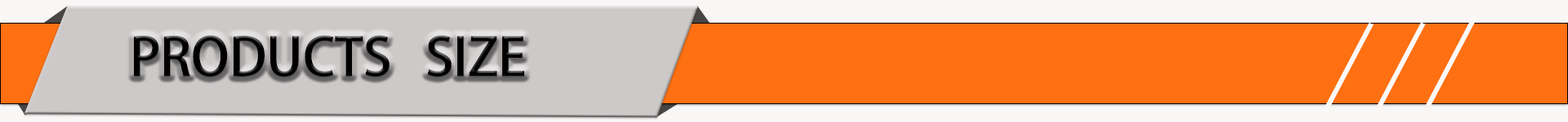

Size of Wire Collated Galvanized Coil Nails

| Coiled Nails - Ring Shank | |||

| Length | Diameter | Collation Angle (° ) | Finish |

| (inch) | (inch) | Angle (° ) | |

| 2-1/4 | 0.099 | 15 | Galvanized |

| 2 | 0.099 | 15 | bright |

| 2-1/4 | 0.099 | 15 | bright |

| 2 | 0.099 | 15 | bright |

| 1-1/4 | 0.090 | 15 | 304 stainless steel |

| 1-1/2 | 0.092 | 15 | galvanized |

| 1-1/2 | 0.090 | 15 | 304 stainless steel |

| 1-3/4 | 0.092 | 15 | 304 stainless steel |

| 1-3/4 | 0.092 | 15 | hot dipped galvanized |

| 1-3/4 | 0.092 | 15 | hot dipped galvanized |

| 1-7/8 | 0.092 | 15 | galvanized |

| 1-7/8 | 0.092 | 15 | 304 stainless steel |

| 1-7/8 | 0.092 | 15 | hot dipped galvanized |

| 2 | 0.092 | 15 | galvanized |

| 2 | 0.092 | 15 | 304 stainless steel |

| 2 | 0.092 | 15 | hot dipped galvanized |

| 2-1/4 | 0.092 | 15 | galvanized |

| 2-1/4 | 0.092 | 15 | 304 stainless steel |

| 2-1/4 | 0.090 | 15 | 304 stainless steel |

| 2-1/4 | 0.092 | 15 | hot dipped galvanized |

| 2-1/4 | 0.092 | 15 | hot dipped galvanized |

| 2-1/2 | 0.090 | 15 | 304 stainless steel |

| 2-1/2 | 0.092 | 15 | hot dipped galvanized |

| 2-1/2 | 0.092 | 15 | 316 stainless steel |

| 1-7/8 | 0.099 | 15 | aluminum |

| 2 | 0.113 | 15 | bright |

| 2-3/8 | 0.113 | 15 | galvanized |

| 2-3/8 | 0.113 | 15 | 304 stainless steel |

| 2-3/8 | 0.113 | 15 | bright |

| 2-3/8 | 0.113 | 15 | hot dipped galvanized |

| 2-3/8 | 0.113 | 15 | bright |

| 1-3/4 | 0.120 | 15 | 304 stainless steel |

| 3 | 0.120 | 15 | galvanized |

| 3 | 0.120 | 15 | 304 stainless steel |

| 3 | 0.120 | 15 | hot dipped galvanized |

| 2-1/2 | 0.131 | 15 | bright |

| 1-1/4 | 0.082 | 15 | bright |

| 1-1/2 | 0.082 | 15 | bright |

| 1-3/4 | 0.082 | 15 | bright |

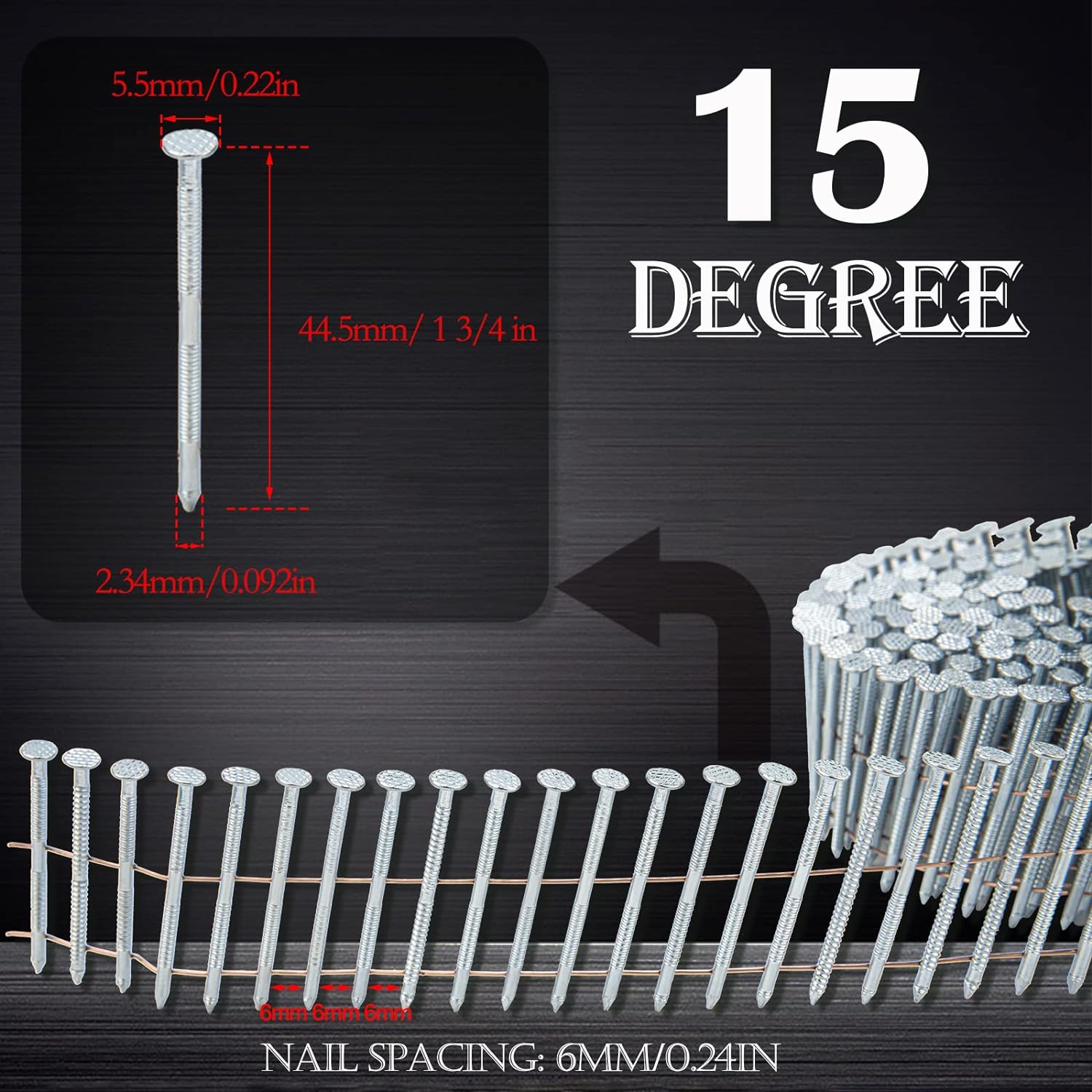

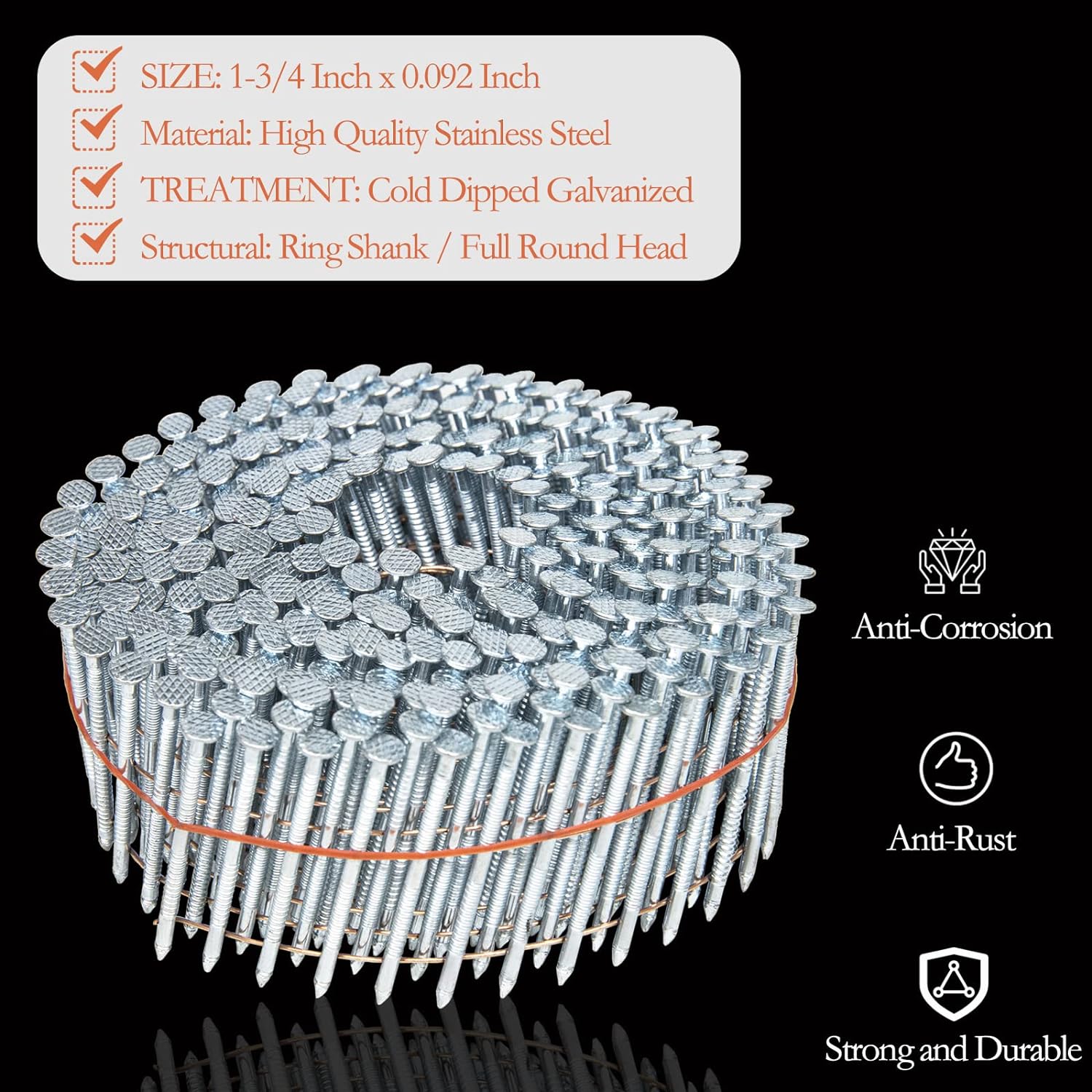

Product show of Coil Framing Nail

Product Video of 15degree Wire Pallet Coil Nails

Application of Cold-Dipped Galvanized Coil Nails

Cold-dipped galvanized coil nails are commonly used in a variety of construction and carpentry applications where corrosion resistance and strong holding power are essential. The cold-dipped galvanized coating provides excellent protection against rust and corrosion, making these nails suitable for both interior and exterior use.

Some common uses for cold-dipped galvanized coil nails include:

1. Exterior siding installation: These nails are often used to secure siding materials to wooden surfaces, providing a durable and weather-resistant attachment.

2. Roofing projects: Cold-dipped galvanized coil nails are suitable for fastening roofing materials, such as shingles and underlayment, providing long-lasting protection against the elements.

3. Deck construction: These nails are often used in the construction of outdoor decks and patios, where they provide strong and corrosion-resistant fastening for decking boards and structural components.

4. Framing and sheathing: Cold-dipped galvanized coil nails can be used in framing and sheathing applications, providing a secure attachment for structural components and wall sheathing materials.

Overall, cold-dipped galvanized coil nails are a versatile and reliable option for a wide range of construction projects, particularly those requiring durable and corrosion-resistant fastening solutions.

The packaging for Roofing Ring Shank Siding Nails can vary depending on the manufacturer and distributor. However, these nails are typically packaged in sturdy, weather-resistant containers to protect them from moisture and damage during storage and transportation. Common packaging options for Roofing Ring Shank Siding Nails may include:

1. Plastic or cardboard boxes: Nails are often packaged in durable plastic or cardboard boxes with secure closures to prevent spillage and keep the nails organized.

2. Plastic or paper-wrapped coils: Some Roofing Ring Shank Siding Nails may be packaged in coils wrapped in plastic or paper, allowing for easy dispensing and protection against tangling.

3. Bulk packaging: For larger quantities, Roofing Ring Shank Siding Nails may be packaged in bulk, such as in sturdy plastic or wooden crates, to facilitate handling and storage on construction sites.

It's important to note that the packaging may also include important information such as nail size, quantity, material specifications, and usage instructions. Always refer to the manufacturer's guidelines for proper handling and storage of Roofing Ring Shank Siding Nails.

1. Q: How to order?

A:

Please send us your purchase order by Email or Fax,or you can ask us to send you Proforma Invoice for your order.We need to know the following information for your order:

1) Product information:Quantitiy,Specification(size , color, logo and packing requirement),

2) Delivery time required.

3) Shipping information:Company name,Address,Phone number,Destination seaport/airport.

4) Forwarder's contact details if there is any in China.

2. Q: How long and how to get sample from us ?

A:

1) If you need some sample to test,we can make as per your request,

you need to pay for the transportation freight by DHL or TNT or UPS .

2) Lead time for making sample:about 2 working days.

3) The transportation freight of samples: the freight depends on the weight and the quantity .

3. Q: What is the payment terms for sample cost and order amount?

A:

For sample, we accept the payment sent by West Union,Paypal, for orders, we can accept T/T.